Based on successful and very popular BD11 design, with updated BD12 Geometry.

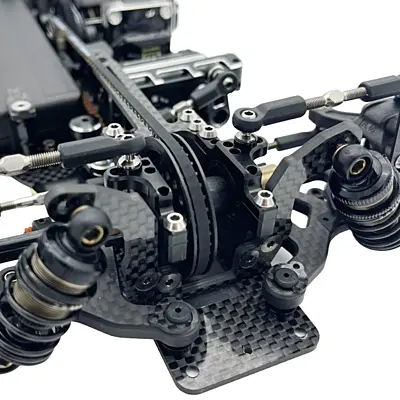

Firstly, we decided to make the tower one piece which joins underneath the spool pulley. This helps provide improved rigidity of the bulkheads and also slightly reduces the sideways flex in the tower, improving consistency and corner speed. It also keeps the tower more square on each side. It is also machined from hard weave carbon which significantly increases the stiffness of the tower over the original, and our BD11 one to further improve rigidity of the front bulkheads.

We also moved the side of the tower so it doesn't rest on the bulkhead. This allows the tower to flex more independently of the bulkhead, ensuring large forces through the shocks get soaked up by the tower and not forced into the bulkheads. Basically, it allows the tower to flex more independently from the front bulkheads.

Lastly, the tower self locates on countersunk screws (not supplied - we recommend M3x6) which self centre. The standard tower has some play and also button head screws, which means its easy to tweak in a crash or be tightened up on the wrong angle. Countersunk screws will automatically pull towards the centre and self-centre the tower. They, combined with the stiff carbon and 1pc design make the tower much less susceptible to moving upon impact.

Features:

- One piece design for increased rigidity and accuracy

- "Off bulkhead" design for more independent flex of the tower and bulkhead

- Machined from Stiff Weave Carbon Fibre for improved rigidity and strength

- Self-centering countersunk screw design for increased accuracy and reduced tweak

- CNC Machined in House from Stiff Weave 3K Gloss Carbon Fiber